Our scope of service

Mevas Crane Inspectors’ main service is the pre-purchase inspection of used cranes. Over the years we have inspected a wide range of equipment. A special inspection sheet has been prepared for each specific type of crane. This way the inspector does not forget to check any point.

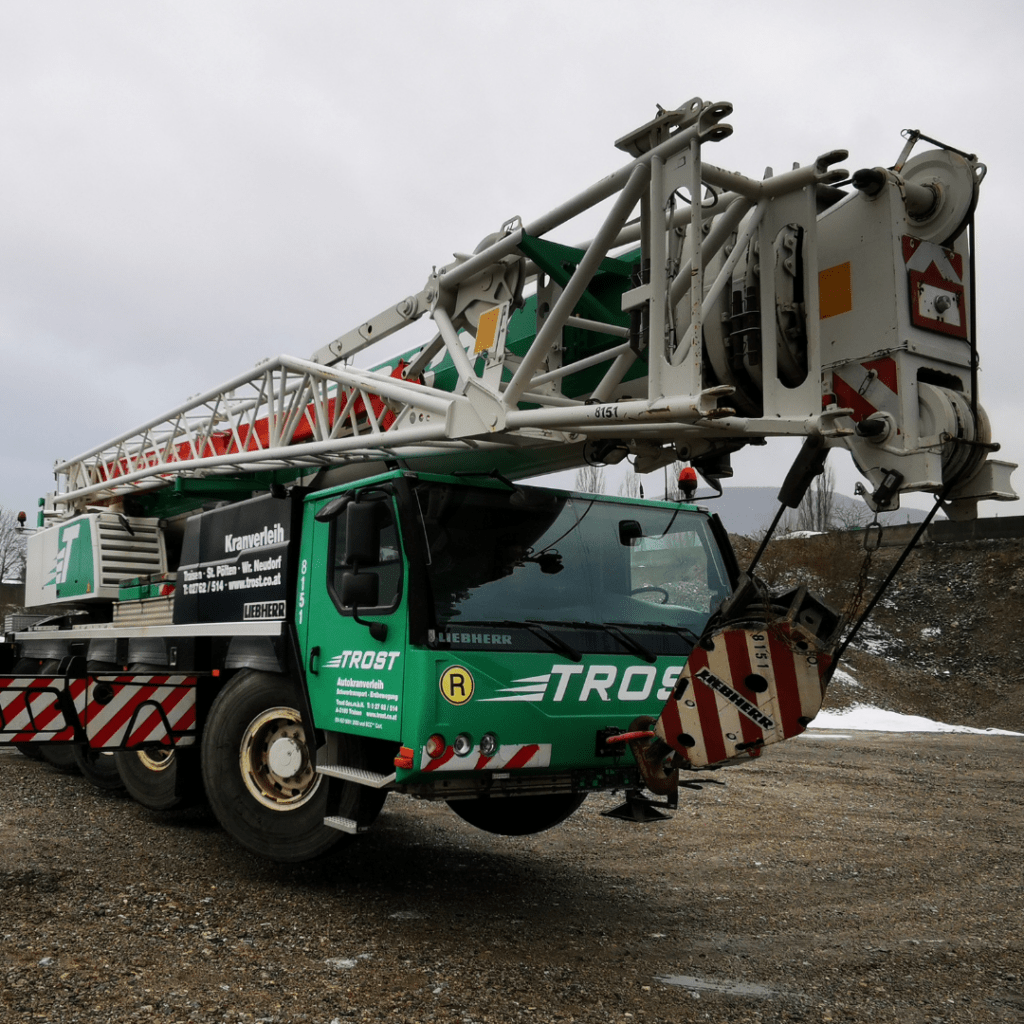

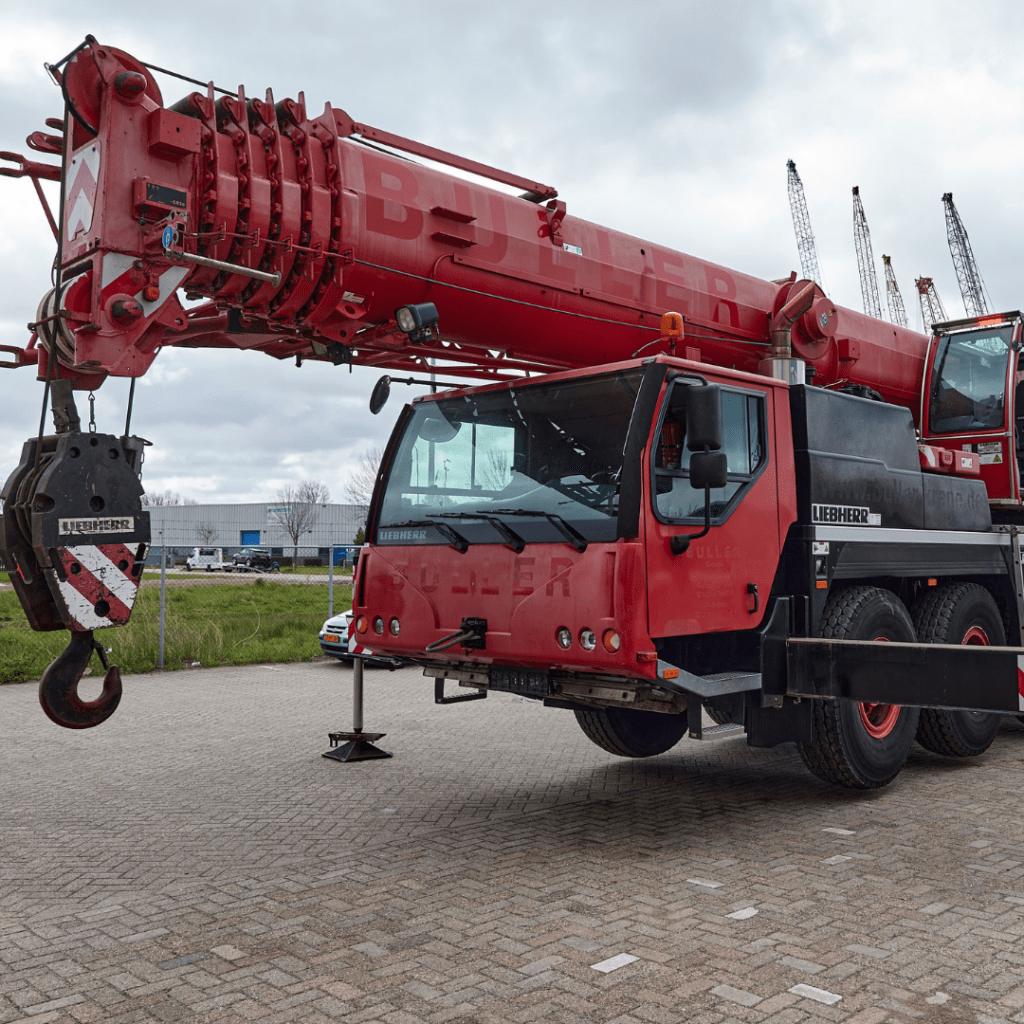

Mobile & ATT Crane Inspections

We carry out inspections for mobile cranes in the presence of a crane operator. The all-terrain-crane is supported, ballasted and all functions are tested. Telescoping, winch function, slewing and load moment limitation. The engineer checks ropes, jibs, hook blocks, rollers and all hydraulic components. Depending on the situation, the function of the crane undercarriage is checked before or after the crane inspection: Driving, shifting, braking. The motors and the cooling system are checked. Certain parameters on the crane would also be measured.

- Inspection for used Mobile and ATT cranes

- Inspection for used Crawler Cranes

- Valuation for all kind of cranes (finance, treassury, M&A)

- Inspection and Valuation of Harbour Cranes

- Repair Cost Analysis and Damage Calculation

- Pre Shipping Inspections PSI new and used cranes

Crawler Crane Inspections

The inspection of a crawler crane is similar to that of a mobile crane. Additional task is the inspection of the lattice mast, the guy or derrick and the jibs. Some cranes have a extendable or suspended ballast (supra-lift). In the case of special versions, the winch synchronisation may also be checked. Last but not least an inspection of the undercarriage and chassis has to be performed. Almost similar happens the inspection of dragline excavators and crawler cranes for civil engineering work.

Crane valuation for mobile and crawler cranes

In the life cycle of a crane, it will occasionally be necessary to answer the question of what the machine is still worth at a certain point in time. The question is either the current market value or what the crane is worth at a certain point in its life. The book value is simply determined by the owner according to depreciation. However, this does not represent the actual current value. It will therefore sometimes be necessary for an independent body to determine the actual residual value of the machine.

Our team has extensive experience with valuation reports for cranes. In the course of the company’s history, we have analysed the values of over 80 mobile cranes, truck-mounted cranes, chain cranes and even harbour cranes. Our valuations are usually accompanied by an on-site inspection and a defect survey. Repair costs are calculated and the damage to the crane is documented.

In exceptional cases, an online assessment can also be carried out based on the data provided.

We can realise this service for a single crane or an entire rental fleet in a short space of time. We have references for larger projects that we have successfully realised.

Examination of Reach Stackers

Not exactly a crane but a lifting equipment as well: The Reach Stacker is a machine to lift and transport containers in a port. Our technicians have inspected at least 40 of these lifting devices over the last few years. There is also a checklist for container stackers and an inspection guide for the mechanic carrying out the inspection. We pay particular attention to checking whether the forklift is capable of carrying a heavy container up to the maximum lifting height. The load indicator is observed during lifting. We check whether the hydraulic system and the engine are capable of providing the required performance under normal operating conditions.

Harbor Crane Inspection and Evaluation

If there is a change of ownership for harbour cranes or if there is a change of operations in the port, or if a harbour crane is to be sold, an inspection and assessment by an independent third party is often necessary. Part of our range of services includes the inspection and assessment of used cranes of all kinds. This also includes cranes and large handling machines in the harbour. Read more here.

Inspection Report, Crane Checklist

We have a specific checklist for each type of crane. This ensures that the inspector does not forget any component. Our customers receive the inspection report as a PDF document. This document can be viewed on the PC as well as printed out. Everything is noted down on just two pages. Buyers of second-hand cranes can use our checklist to assess from home whether the used crane is a good investment.

Inspections for heavy earthmoving equipment

Another division of MEVAS deals with the inspection of earth-moving machinery, excavators, wheel loaders, dump trucks and road construction machinery. For information on this service area, we would like to ask you to visit the website www.mevas.net.