Ανεξάρτητες επιθεωρήσεις πριν από την παράδοση για μεταχειρισμένους γερανούς από Γερμανούς εμπειρογνώμονες

Μην πληρώνετε καλά χρήματα για έναν κακό γερανό

Η αγορά ενός μεταχειρισμένου γερανού -είτε πρόκειται για κινητό γερανό, γερανό φορτηγού, γερανό πύργου ή μοντέλο παντός εδάφους- ενέχει κινδύνους. Οι γερανοί λειτουργούν κάτω από ακραίες συνθήκες και η κακή συντήρηση είναι πιο συχνή απ’ ό,τι νομίζετε. Κρυφά ελαττώματα, όπως ραγισμένοι βραχίονες, διαρροή κιβωτίων ταχυτήτων ή κατεστραμμένα σχοινιά, μπορεί να σας κοστίσουν χιλιάδες σε επισκευές. Ακόμα και μικρά ζητήματα, όπως φθαρμένα φρένα ή ελαττωματικά όργανα μέτρησης, μπορούν γρήγορα να αθροιστούν.

Σε αυτό το σημείο ερχόμαστε εμείς.

Στη Mevas, οι ανεξάρτητες επιθεωρήσεις τρίτων διενεργούνται από έμπειρους Γερμανούς μηχανικούς που ειδικεύονται στους μεταχειρισμένους γερανούς και τον ανυψωτικό εξοπλισμό. Παρέχουμε αμερόληπτες, εξειδικευμένες αξιολογήσεις, ώστε να μπορείτε να λαμβάνετε τεκμηριωμένες αποφάσεις αγοράς και να αποφεύγετε δαπανηρές εκπλήξεις.

Πώς λειτουργεί

- Βρήκατε έναν γερανό; Επικοινωνήστε μαζί μας.

Στείλτε μας το όνομα και τα στοιχεία επικοινωνίας του πωλητή. Εμείς θα αναλάβουμε τα υπόλοιπα. - Προγραμματίζουμε την επιθεώρηση.

Ο επιθεωρητής μας θα συντονιστεί με τον πωλητή για να προετοιμάσει τον γερανό για πλήρη έλεγχο -εξασφαλίζοντας ότι είναι διαθέσιμος ένας έμπειρος χειριστής. - Επιθεωρούμε κάθε λεπτομέρεια.

- Επαλήθευση της διαμόρφωσης και του σειριακού αριθμού

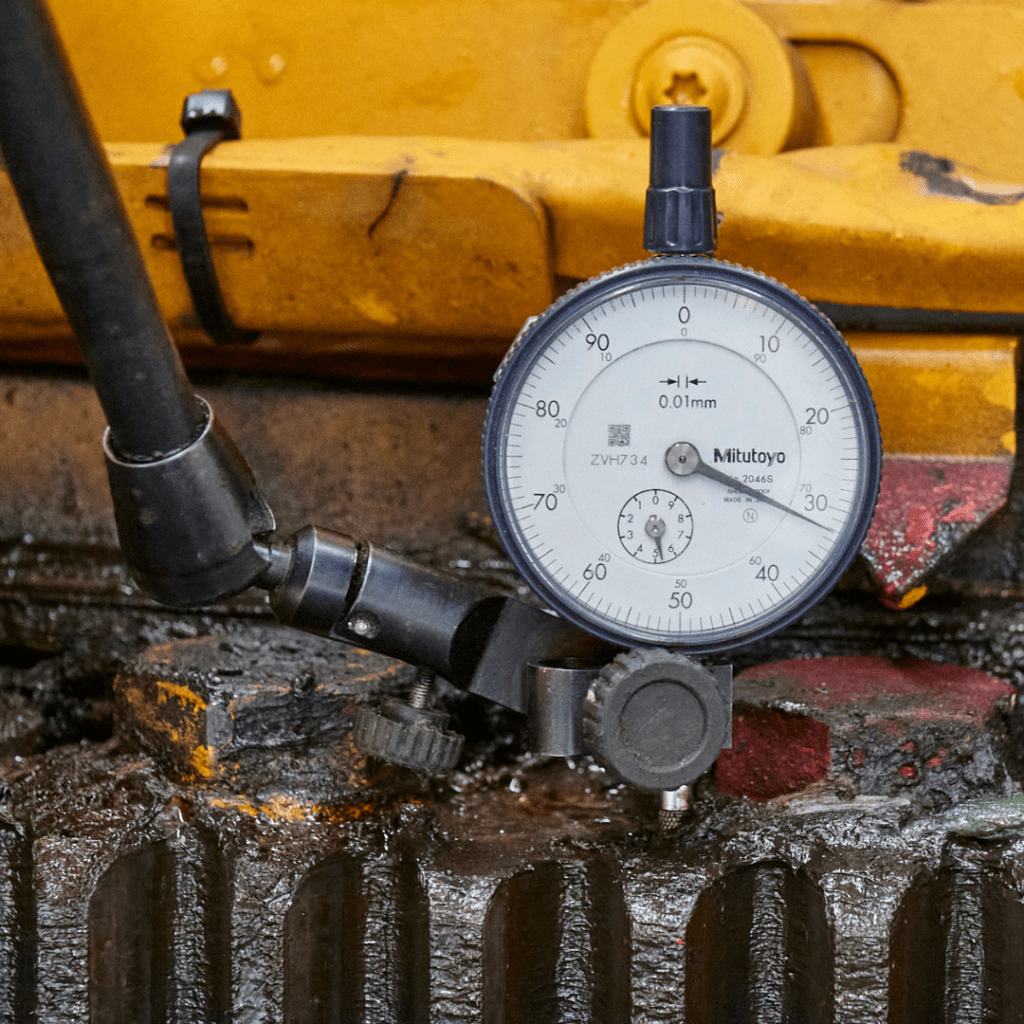

- Οπτική επιθεώρηση για ρωγμές, διαρροές και φθορά

- Πλήρης δοκιμή λειτουργίας των υδραυλικών συστημάτων, των βραχιόνων, των σχοινιών και του LMB

- Επιθεώρηση του φορέα, συμπεριλαμβανομένων των φρένων και της μετάδοσης κίνησης

Λαμβάνετε λεπτομερή έκθεση.

Παραδίδουμε μια ολοκληρωμένη γραπτή έκθεση με ευρήματα, φωτογραφίες όλων των θεμάτων και επαγγελματικές συστάσεις.

[Κάντε κλικ εδώ για να δείτε ένα δείγμα έκθεσης ]

Επιθεωρούμε επίσης περονοφόρα ανυψωτικά μηχανήματα και χειριστές εμπορευματοκιβωτίων

Από ένα περονοφόρο ανυψωτικό 1,5 τόνων έως έναν χειριστή εμπορευματοκιβωτίων 40 τόνων – επιθεωρούμε ένα ευρύ φάσμα ανυψωτικού εξοπλισμού. Η ομάδα μας ελέγχει τη γενική κατάσταση, μετρά την επιμήκυνση της αλυσίδας και εκτιμά το κόστος επισκευής για να σας βοηθήσει να επιλέξετε το καλύτερο μηχάνημα για την επένδυσή σας.

Προσφερόμενες υπηρεσίες επιθεώρησης: Υπηρεσίες επιθεώρησης:

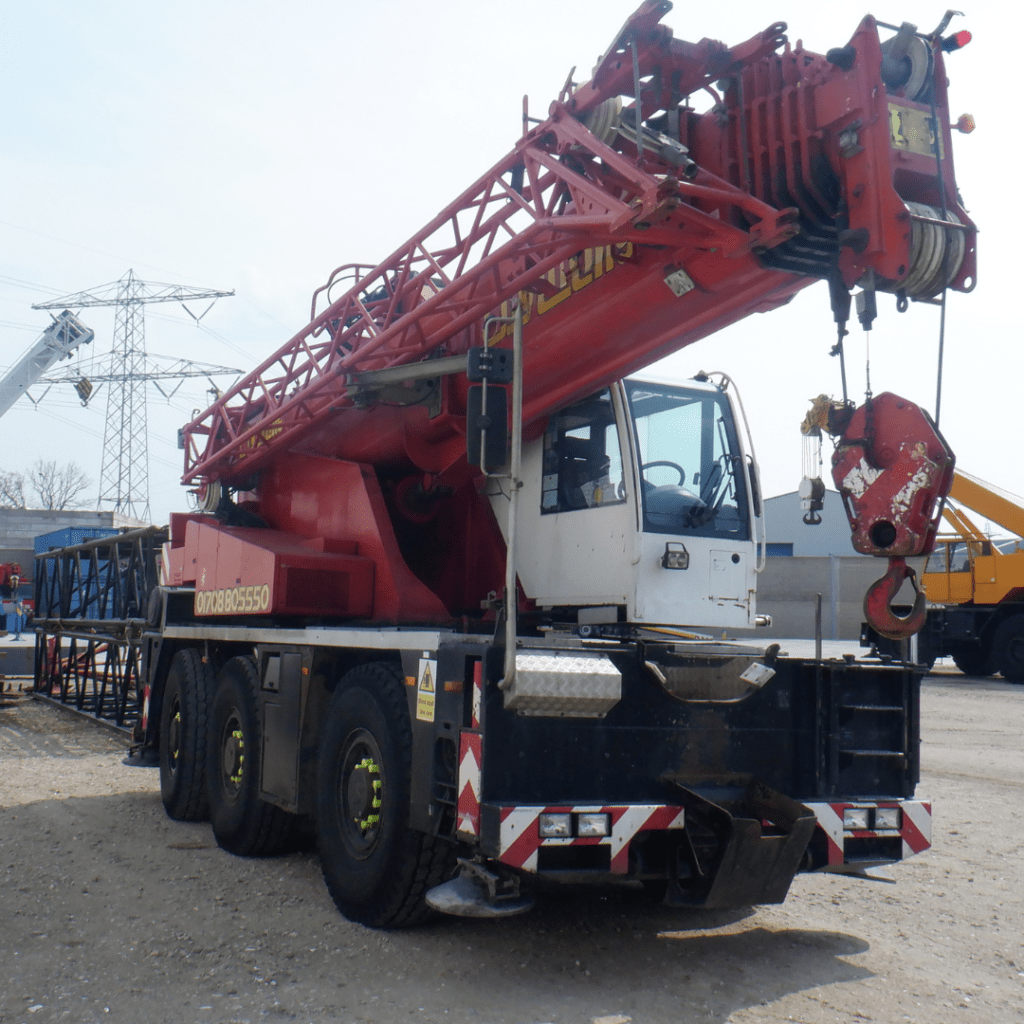

✅ Επιθεώρηση κινητών γερανών

✅ Επιθεώρηση γερανών που τοποθετούνται σε φορτηγά

✅ Επιθεώρηση γερανών πύργου

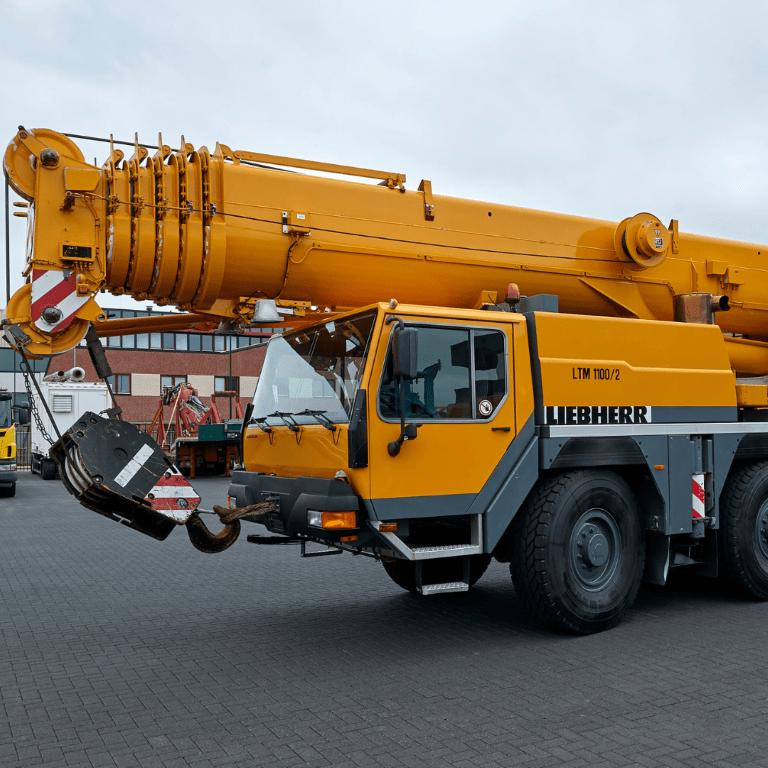

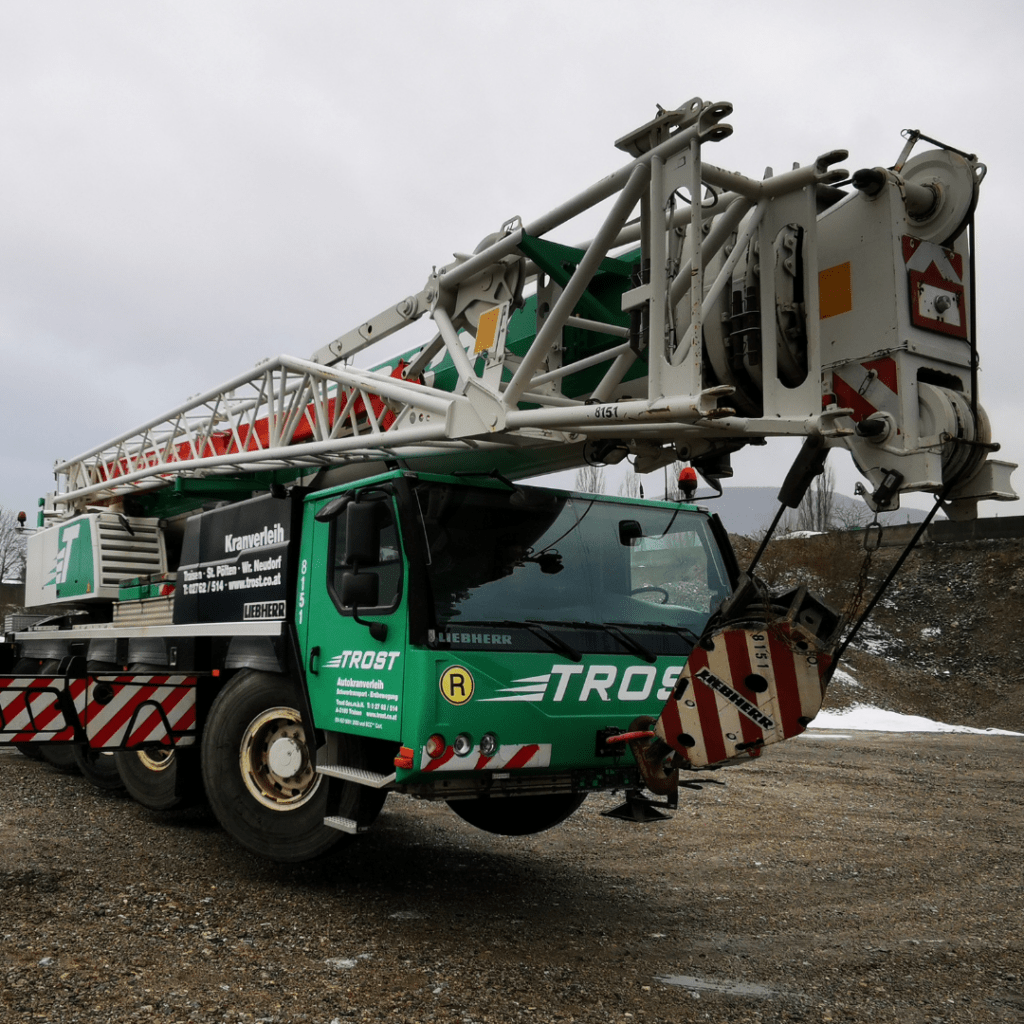

✅ Επιθεώρηση γερανών παντός εδάφους

✅ Επιθεώρηση γερανού δικτυωτού βραχίονα

✅ Επιθεώρηση γερανού λιμένα

✅ Επιθεώρηση τηλεσκοπικού γερανού

✅ Επιθεωρήσεις περονοφόρου ανυψωτικού οχήματος και στοιβαχτή προσέγγισης

Μάρκες που γνωρίζουμε

Επιθεωρούμε εξοπλισμό από κορυφαίους κατασκευαστές, συμπεριλαμβανομένων των ακόλουθων:

Tadano-Faun, Liebherr, Grove, Locatelli, Kato, Kobelco, Krupp, Gottwald, Potain, Linde, Hyster, Yale, Jungheinrich, Caterpillar και πολλά άλλα.

Μπορείτε επίσης να παρακολουθήσετε ένα βίντεο σχετικά με τις υπηρεσίες επιθεώρησης γερανών.

Δωρεάν λίστα ελέγχου επιθεώρησης γερανών

Ίσως πέσατε πάνω στον ιστότοπό μας κατά τη διάρκεια μιας αναζήτησης για μια δωρεάν λίστα ελέγχου επιθεώρησης γερανών ή ένα έντυπο επιθεώρησης γερανών. Οι λίστες ελέγχου για την επιθεώρηση μεταχειρισμένων γερανών είναι η καθημερινή μας εργασία και οι επιθεωρητές μας έχουν ένα έντυπο το οποίο χρησιμοποιούν για να επιθεωρήσουν έναν γερανό. Με αυτόν τον τρόπο φροντίζουμε να μην ξεχαστεί κανένα στοιχείο κατά τη διάρκεια μιας επιθεώρησης. Υπάρχει διαθέσιμη δωρεάν έκδοση; Λυπάμαι, δεν υπάρχει.

κατασκευαστής γερανών

- Demag

- Liebherr

- Tadano & Faun

- Terex

- PPM

- Grove

- Wolf & Peiner

- Spierings