How do you go about inspecting a used crane?

To understand how to go about inspecting a used crane for a buyer, you first have to be clear about the situation you will encounter on site. It is very often the case that cranes are traded by brokers. This means that the cranes are often still in use and being operated by the owners. It is therefore important to discuss with the operator exactly when an inspector will come and how long he will need to inspect the crane. We provide this service. We call the operator, make an appointment and ensure that the driver is available.

Operational tests for used cranes

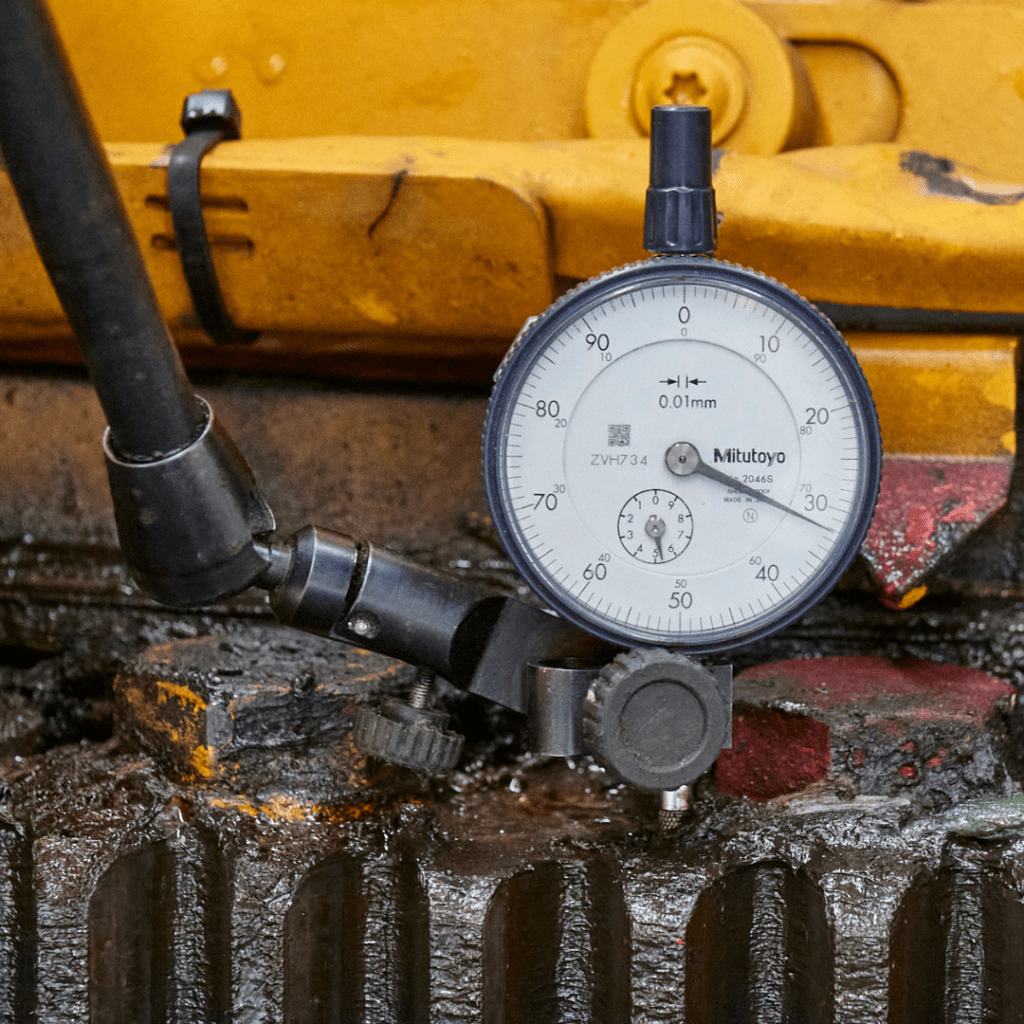

When inspecting a used crane, we usually proceed as follows: the inspector sets up the crane together with the driver. The outriggers are extended and the crane is levelled. Then a detailed function test is carried out with the crane driver. The boom is telescoped and it is observed whether the segments extend smoothly. The cable is completely lowered and checked for damage or twists. The slewing function is checked. The inspector measures the vertical tilting clearance at the slewing ring. After a visual inspection of all components, the brakes and the drive are tested. To do this, we drive the crane a little way. Final test, check the retarder and observe whether the gears shift smoothly.

Video with impressions of Mevas crane inspections

Of course, all the other functions of the crane are also checked. This includes, for example, testing the tilting cab or checking whether the catwalk extends.

When all the functions have been tested, the motors are examined closely. Are there any unusual signs of wear, such as a high blow-by rate, are liquids such as oil or coolant contaminated, or are there leaks at the turbocharger or at the accessory drive?

Visual inspection

Checking for leaks is an important part of the inspection for used cranes. During the function test, the inspector checks whether the lifting cylinder or the telescopic cylinder of the crane has leaks or damage. Furthermore, the functionality and leaks of the winches and slewing gear are checked during the test.

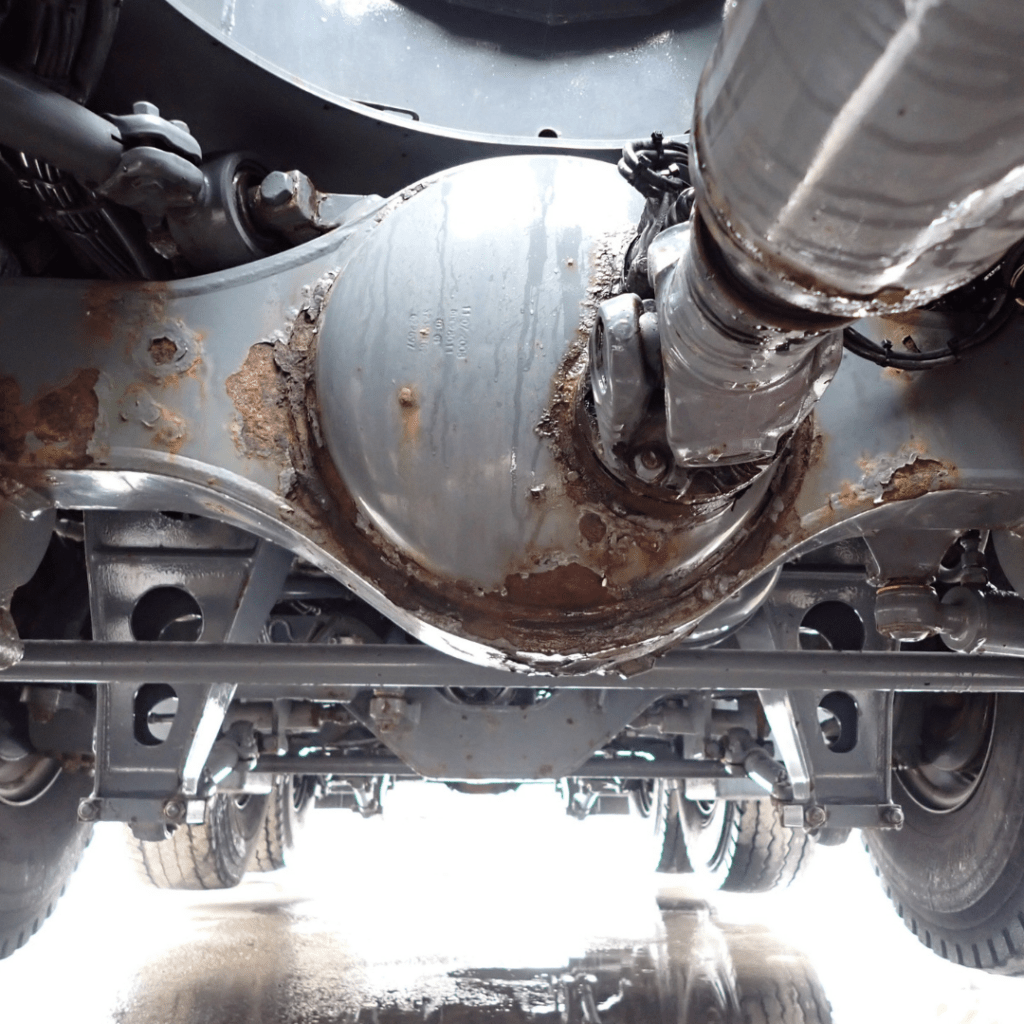

After this visual inspection, the inspector moves under the crane. He checks all axles, the steering cylinders and all suspension cylinders for damage and leaks. As far as they are accessible, the brake shoes and brake linings are also inspected at the same time. From below, it is also best to check for leaks in the transmission, transfer case and engine oil pan. Our inspectors are not afraid of getting dirty during such an inspection.

This description applies primarily to mobile cranes and rough-terrain cranes. By contrast, the final drives and the running gear are closely inspected in crawler cranes. The so-called rotary feedthrough is checked for leaks from the underside. All structures and chassis are checked for cracks and welds in all cranes.

Aids in ensuring that nothing is overlooked: the crane checklist

Given the complexity and scope of an inspection for mobile or crawler cranes, it is easy for the inspector to miss something or forget a check. That is why MEVAS crane inspectors work according to a detailed inspection list. There is a specially designed checklist for each type of construction. The inspector can see at a glance which components he has not yet checked or where he has forgotten a note. This ensures that all components are inspected and evaluated when a used crane is inspected.

Experienced Crane Inspectors

Of course, there is no problem in ordering a technician directly from Liebherr, Tadano or Terrex to inspect a crane. However, these inspectors are often very expensive, and the prices for inspecting a used crane are greatly increased the further they have to travel. On the other hand, mechanics who repair cranes often do not understand the requirements for inspecting a used machine. Our inspectors are less concerned with safety checks, but are trained to look for certain details on used cranes and to give less weight to certain details. We know what the buyer of a used crane requires and create an inspection report exactly as the buyer wants it. This provides the buyer with all the information necessary to make a purchase decision from home. Depending on the location, a professional crane inspection with us costs approximately 900 to 1300 US dollars. Please send us detailed information about the type and location of the crane. We will provide you with a quote shortly.

By the way, we don’t talk about the machines we’ve seen somewhere and we don’t share crane inspection reports with third parties. All information is treated confidentially. Have your crane inspected by a professional before you buy it and don’t buy an old lemon.