How much tilting play is allowed in the slewing ring of a mobile or a crawler crane?

Ask three specialists and you will get three different answers. If you ask Liebherr, i.e. the people who would like to sell you a repair or a new slewing ring, you will get the statement that the tolerance limit would be reached at 0.9 mm tilting play. If you ask a mobile crane user in Eastern Europe or Africa, they will say anything under 5mm is fine.

What does a crane inspector say about swing bearing play?

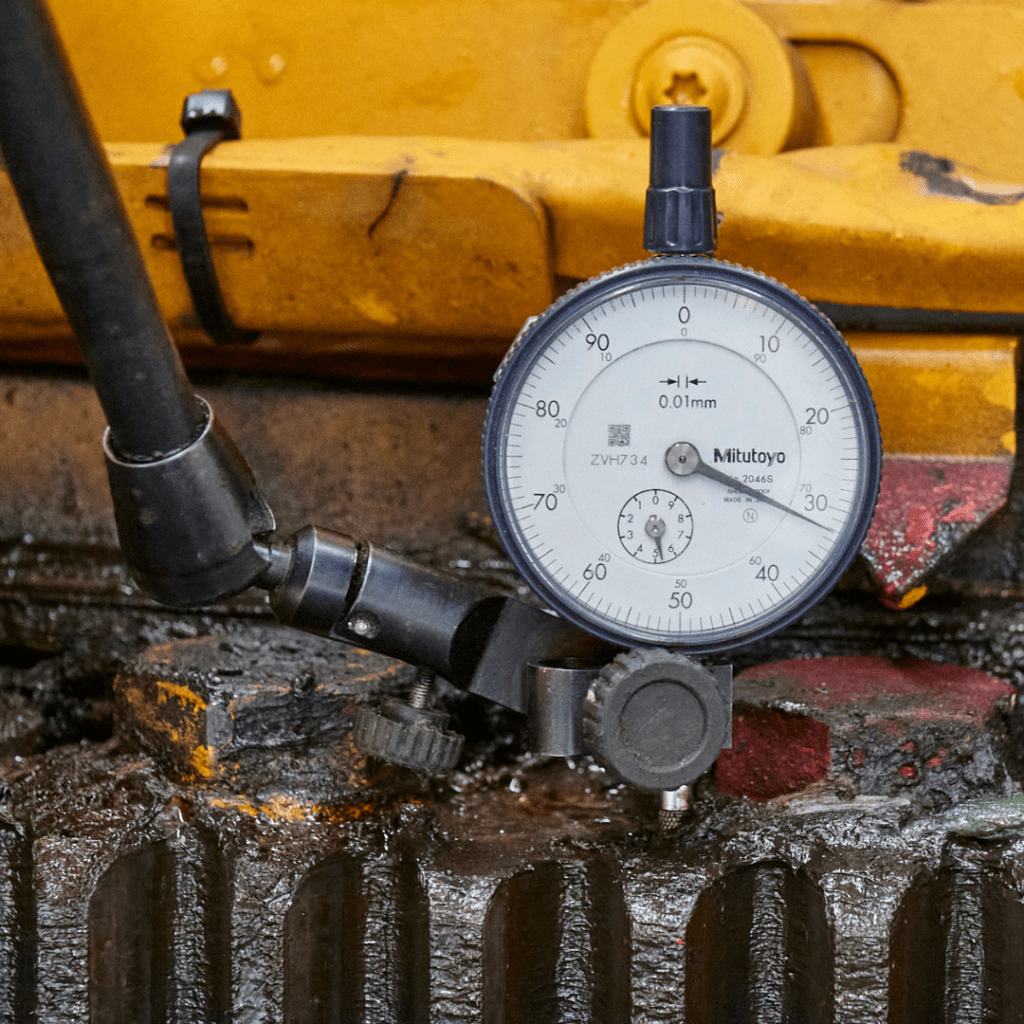

As inspectors of used cranes, what is our opinion on this? Since the tilting play in the slewing ring is sometimes 0.3 to 0.6 mm even on new cranes, we do not think it is necessary to criticize a slewing ring if it has less than 1.2 mm tilting play. To know exactly, you should also measure the slewing ring play over at least three or four sides. Experienced inspectors know exactly how the procedure must be carried out. It is particularly important that the crane is ballasted. When we inspect a used mobile crane, we typically only measure across one side. Only when there are doubts about the condition is it measured over several pages.

Why is it important to measure swing bearing play from time to time on a mobile crane?

Measuring swing bearing play on a mobile crane is crucial for several reasons, and it plays a significant role in ensuring the safe and efficient operation of the crane. Here are some key reasons why it’s important to regularly measure swing bearing play:

- Safety:

- Excessive swing bearing play can compromise the stability and structural integrity of the crane, leading to potential accidents or tip-overs. Regular measurements help identify issues before they become critical, ensuring the safety of both operators and bystanders.

- Equipment Longevity:

- Monitoring swing bearing play allows early detection of wear and tear. Addressing any play or movement issues promptly helps prevent further damage to the swing bearing and other related components, thus extending the overall lifespan of the crane.

- Operational Performance:

- Properly functioning swing bearings are essential for smooth crane operation. Excessive play can lead to imprecise control and reduced accuracy during lifting and positioning tasks. Regular measurements help maintain optimal operational performance.

- Imagine a crane has the boom extended to 80 or more meters and there is 5mm play on swing bearing. On getting load the tip would reduce height and angle of boom significantly.

- Preventive Maintenance:

- Regularly checking swing bearing play is a part of preventive maintenance practices. Identifying and addressing potential problems early can prevent more extensive and costly repairs in the future, minimizing downtime and maximizing crane availability.

- Regulatory Compliance:

- Many regulatory bodies and safety standards require periodic inspections and maintenance of crane components, including swing bearings. Regular measurements help ensure compliance with these regulations and standards, reducing the risk of legal and financial consequences.

- Cost Savings:

- Proactive maintenance based on regular measurements can be more cost-effective than reactive repairs. Early identification and correction of swing bearing issues help avoid major breakdowns and the associated costs of emergency repairs and crane downtime.

- Reliability:

- A crane with a well-maintained swing bearing is more reliable and less likely to experience unexpected failures. This reliability is crucial in construction and industrial settings where cranes play a vital role in various operations.

In summary, measuring swing bearing play on a mobile crane is essential for maintaining safety, extending equipment life, ensuring optimal performance, complying with regulations, and ultimately minimizing costs associated with repairs and downtime. Regular inspections and maintenance contribute to the overall reliability and efficiency of the crane in its operational environment.

How much does it cost to replace a worn slewing bearing?

Depending on size and lifting capacity of a crane or an excavator the swing bearing itself can easily cost above 8.000 Euro. Then you need all the pins to fix it on superstructure and chassis. That’s another 1.500 Euro at least. But with this cost the slew ring hasn’t been exchanged yet. Cranes are required to lift the superstructure. You need big tools to open and fit the pins with appropriate torque. All in all the replacing cost for a sllew ring will be in most cases far above 10.000 Euro.

For the reason of the big cost it is strongly recommended to measure the play if you are buying a crane or a larger excavator. Hire an expert to inspect a used crane and check out those details.